What do you need to know about digital twins?

Digital twins are the talk of the town. If you want to know more about them and even create your own, read on…

When a new term shows up on the market, we always ask ourselves if this term is just a buzzword or real stuff popping up. One of the expressions everyone makes sure they have in their sales pitch for digitalization is the digital twin. How do you know if this new terminology is already a fact or just another buzzword?

I always like to find an example to explain this technical stuff to everyone. When the topic is digital twin, I do believe we can use ourselves as an example. So, try to visualize a future not so far away from today, where all human beings can have a digital version of themselves.

But why are we going to need a virtual version of ourselves? In this scenario, the virtual version of our bodies is always kept up to date with our health condition. Now it can run a series of digital tests, also known as simulations, to find potential health problems before they happen.

I know, it sounds crazy, right? However, after its implementation, the virtual simulation will be responsible for increasing the life expectancy by a couple of years. The reason is simple – thanks digital twin technology people will get better at looking after themselves before something happens.

This futurist example gives a general explanation of what a digital twin is. Did you get it? If not, don’t worry, we are going to dive more into details. The idea today is to discuss what a digital twin is, where to implement it, and the benefits of the digital twin for industrial applications.

Yes, a digital twin is a reality, and we’re going to find out about it together.

What is a digital twin?

The digital twin is quite simple to explain; the idea is to create a digital version of a real thing in the cloud of a product, process, or service. Then, with an online connection between the digital version and the real one, it’s possible to run analyses to find out health conditions and prevent potential problems from happening, for example.

Further, the digital twin allows the running of digital simulations, providing a chance to improve processes, prevent unscheduled downtime and much more. The digital twin is not a new topic, but it has become more popular with the new solutions that are appearing on the market using Internet of Things and Industrial Internet of Things.

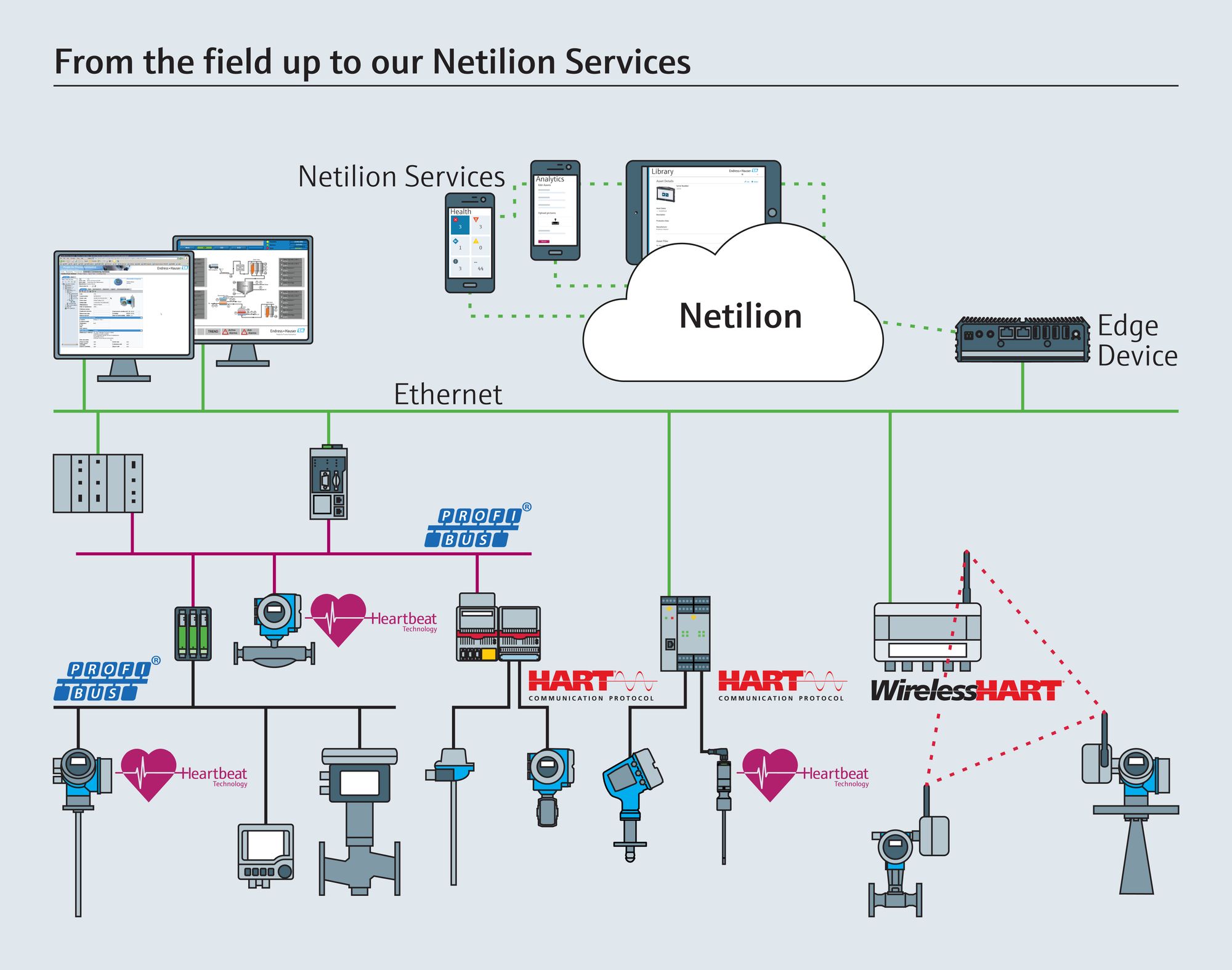

There is a broad range of possibilities for using digital twins in industrial applications. At the same time, there are different implementations of digital twin technology. For instance, as I have said in other articles, the digital twin can be created automatically when you have a connection between the field and the cloud using an edge device.

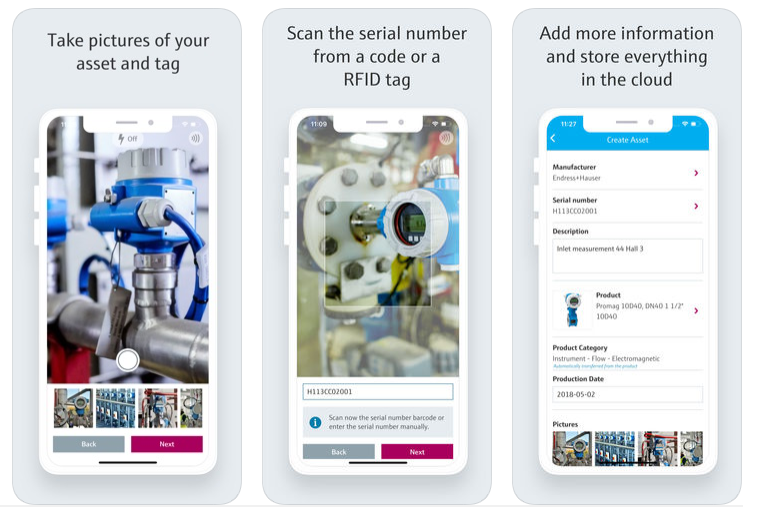

However, it’s also possible to create a digital twin of your device in a different way. For example, scanning the serial number, taking a picture, or adding the information manually to the cloud using your smartphone.

You should also be aware that the Gartner company, one of the world leaders in research and consultation, listed digital twins as one of the top 10 strategic technology trends for 2019. In fact, we can already see a bunch of real applications that use digital twins in the B2B and B2C market.

How do digital twins work?

First off, in most of the cases developed by company experts, the digital twin collects all the data from the devices, analyses them and provides relevant insights to the customer. The R&D department will be responsible for the solution to create the toolkit applying statistics, machine learning, and other mathematical calculations.

The idea is to have a digital version of a physical device that automatically collects all the data from it during its operational lifetime. On top of that, it’s possible to implement algorithms that understand the device performance, check its behavior or provide relevant data regarding the plant’s installed base.

After the development of the tool, it’s necessary to see it working. At this stage, we generate a digital twin for every asset. To do this, we connect all the devices together in a PROFIBUS network, for example, that also has an edge device making the connection to the cloud solution.

When we have established the connection between the IIoT cloud and the edge device, the digital twins of each asset are created automatically in the cloud. This ensures that all the data is collected from field devices and you have a perfect copy of every physical device in the cloud.

Depending on the service implemented in your IIoT platform, the digital twin can be applied in different ways. To understand your database, to find obsolete devices, or to make suggestions for improvements, for example.

What are the benefits of a digital twin?

Digitalization makes all the smart devices in the field provide tons of relevant data all of the time. It’s impossible to understand and interpret all this data manually. Not doing anything is also not good because you are losing an excellent opportunity to understand your application.

When we have a digital twin, the solution integrates with artificial intelligence, machine learning, and other technologies related to Industrial Internet of Things. It’s possible to create digital simulations with online data from physical counterparts.

The digital twin can collect all the information and learn by itself, helping to provide relevant insights regarding improvements in the application or avoiding unscheduled downtime.

Companies are working on open platforms to develop an increasing number of digital twin solutions that interpret the data coming from the physical counterparts connected to the cloud.

More and more, we’re going to see services dedicated to solving daily customer pain that use the same cloud solution. Furthermore, all the insights provided after the digital simulation are usually presented on a dashboard for simple evaluation by your team.

Nowadays, nobody needs to be a data expert to understand what’s going on.

Why is digital twin important to IIoT?

When we talk about IIoT or Industry 4.0, we are referring to smart devices. These smart devices provide valuable data all the time. This is in contrast to the standalone solutions we often had in the past in the industrial environment.

It’s possible to connect these devices to the cloud and use digital twins to create a virtual version of them. Later, during operation, all data are collected in the cloud, and the digital twin can learn how its counterpart ticks.

The solution can be enhanced by using an analytics tool to interpret the data and present it in a way the whole team understands. Analytical services can be developed to different ends, such as a smart system for a particular application, installed base analysis, and more.

Example of digital twin application

What if you could try a digital twin application, right now? Yes, let’s try it out and see how a digital twin works in real life. First off, you need to create your free account here then we can go forward and try Netilion Analytics.

Netilion Analytics helps you to register and organize all your assets in the cloud. It quickly shows you potential improvements to your installed base. You can see the obsolete devices, where the devices are installed, evaluate possibilities of standardization and more.

Now, to register your asset, you have different possibilities. Let’s start with the automatic way. If you want to have the digital twin created in the cloud without doing anything, it’s necessary to connect your network to the cloud using an edge device.

Don’t worry, I know you want to test it, and you don’t have an edge device, do you? So, after you create your free account in Netilion, you can use the website to create your device, adding all the information about it manually.

A second possibility is to use the Netilion Scanner App. You can scan the devices, take pictures, add a description and the device’s location. When you’re finished, your digital twin will be available no matter where you are.

Later, when you click in Analytics and then Insights, all the information regarding your installed base will be available. See the diversity of assets, the criticality of the tags, asset obsolescence, etc.

Cool, huh? Have fun with Netilion!

If you like it, don’t forget to share it on your social media.

See ya soon!