What is prescriptive maintenance (RxM) and how do you prepare for it?

Prescriptive maintenance brings industrial maintenance to a higher level, and the Industrial Internet of Things is the key to make it happen. Read this article to learn how and why

We talked about different types of industrial maintenance in our article “What are the types of industrial maintenance and how can IIoT help?” There I explained different perspectives in corrective, preventive, and predictive maintenance.

However, we left one new type out of that article, so today we’ll discuss “the next step,” prescriptive maintenance (also known as RxM). Yes, many industries have yet to achieve predictive, so anything beyond that sounds very unlikely.

But everyone wants solutions to improve operation, so it’s only a matter of time before they see the light. Keeping plants updated with such technology connects directly to Industry 4.0 and the Industrial Internet of Things (IIoT). And upcoming tech-savvy generations have begun stepping into decision-making roles, accelerating this change.

Yup, prescriptive maintenance may happen sooner than you think, so we’d better learn more about it!

What is prescriptive maintenance?

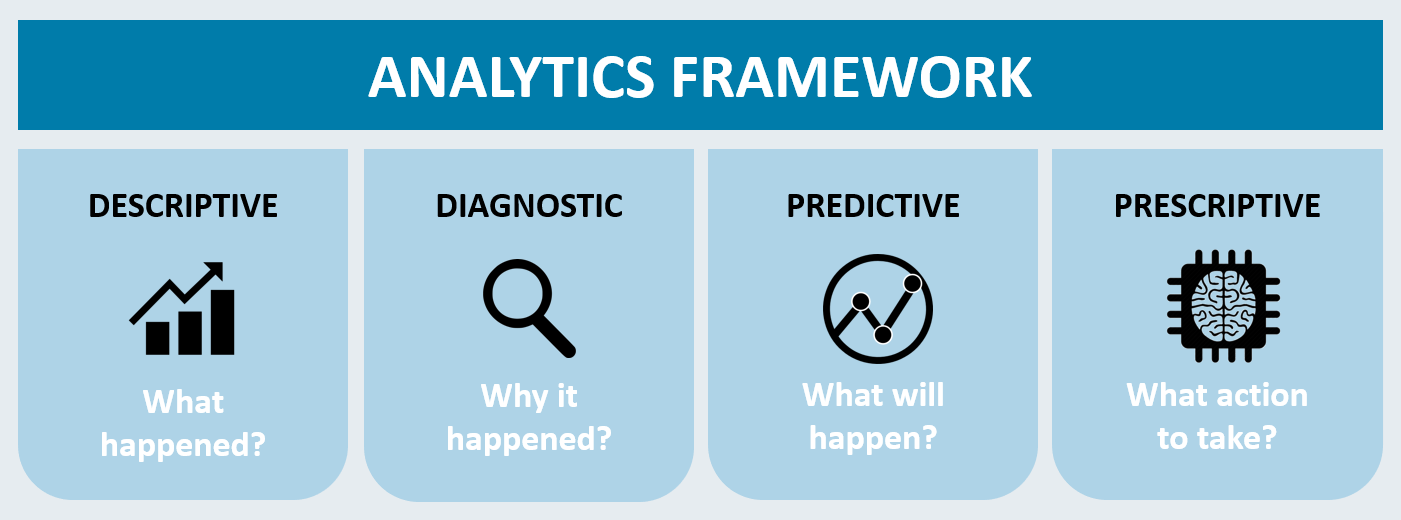

At this level, machine learning and artificial intelligence (AI) provide more than monitoring and simple recommendations. Analytics are an essential part of RxM, to determine what actions to take depending on all the data collected and analyzed.

Any machines with smart sensors installed will continuously collect data for the RxM software. The software will analyze that data and make multiple recommendations such as shortening the time between scheduled downtimes, recalibrating devices, or even reducing production.

All of these suggestions can reduce maintenance and risk as well as extend the equipment’s life. Prescriptive maintenance can also reveal why a particular problem or anomaly occurred in the process.

RxM is constant, so after you act to solve a problem, it continues monitoring the process to make sure the action helped. It also suggests new possibilities for improvements.

What’s the difference between predictive and prescriptive maintenance?

Prescriptive maintenance evolved from predictive. Predictive offers constant monitoring and sometimes a few limited recommendations, and not much else beyond that.

Don’t get me wrong – the recommendations from predictive maintenance are super relevant to make improvements and avoid unscheduled downtime. But in most cases, they only cover the devices and can’t analyze other variables.

RxM uses machine learning and AI to gain a larger perspective on the process, making advanced suggestions for improving production, supporting workflow, reducing downtime, and much more.

While predictive maintenance has yet to reach many industries, IIoT services are flooding the market. Plants that want to survive the tech tsunami will have to invest in stronger structures for their processes.

Fortunately, easy-to-use IIoT services like Netilion from Endress+Hauser remove the barriers of complexity and cost, making digitalization achievable for even the most conservative companies.

What are examples of prescriptive maintenance?

Prescriptive analytics have tons of possibilities, but the concept is so new that finding applications in real environments can be challenging. Early adopters mostly use it on a small scale and usually outside the process automation world.

So far, we’re only seeing it in parts of processes instead of throughout entire runs. However, those segments can provide pieces of the performance picture by measuring certain points, then analyzing the data gathered. RxM can provide suggestions as specific as “increase X by 20 percent for a Y-percent increase in production.”

Although we don’t have many prescriptive-analytics tools on the market yet, many experts and leaders agree that RxM could be the next level of support for reliability and best practices. Picture it applied to a big refinery and think of all the money it could save because the plant became more efficient.

What are the barriers to prescriptive maintenance?

Like any other technology, we have some issues that could bog down this new idea.

- Regulations – Of course we have to use it safely. Many traditional methods may remain for now simply because the amount of risk is unknown. For instance, a certain IIoT sensor has to keep employees and property from harm as well as monitor a device. Can it do that? If we don’t know, we’ll have to wait until we do.

- Cost – RxM requires smart sensors, data storage, analytic software, cloud solutions, and more. Companies have to determine how much they can invest and how much value they can gain from its use.

- Culture – And there’s always the old adage, “If it ain’t broke, don’t fix it.” But another adage comes into play here: “Adapt or die.” Companies that continue to do the bare minimum will get left behind.

Modular IIoT solutions can offer baby steps for digitalization in older processes. Some services offer shallow levels of participation to make cost calculations easier, demonstrate the benefits, and gradually change attitudes.

Solution-as-a-Service is a great way to digitalize industrial processes quickly, and solutions such as Netilion Services are ready to make it happen.

How can I accelerate my path to prescriptive maintenance?

It helps tremendously to start small, so you can see how smart sensors, cloud solutions, and remote service can improve parts of your systems.

For instance, with a basic setup, Netilion Services can reveal insights on your current installations, like the health status of various devices. It can also show you how to improve field services by accessing device documentation in a natural way.

Netilion Ecosystem offers many possibilities to boost you from corrective to next level of maintenance. Best of all, you can try it for free to learn how a digital solution can improve your routines.

New digital services like Netilion offer smooth setup and simple operation, so that you can bring your plant into the digital age step by step. Sounds like a plan, right?

If you liked this article, please share it on your social media using the #Netilion tag.

Thanks, and see you soon!