The IIoT quickly explained

What is a cloud? What do I need to know about connectivity? And what "things" are we talking about? Let's clear up some common questions about the Industrial Internet of Things.

The Industrial Internet of Things (IIoT) enables the connection of physical devices, such as those in industrial plants, to the cloud. This allows for the collection and analysis of data from these devices, known as field data, in order to improve efficiency and optimize processes. But how does it work? Let us examine the basics.

Table of Content

- What is a cloud?

- What is it with connectivity and what do I need it for?

- What's the field devices' role in the IIoT? What about 3rd party devices?

- Can I connect my field devices directly to the cloud?

What is a cloud?

In the context of information technology, a "cloud" is defined as a global server network by means of which users with an internet-enabled device are able to save or manage data, execute applications, or retrieve content and services.

For industrial processes, this means: Data from field devices installed in a plant are transmitted to the cloud, mostly via an industrial connectivity solution, to be later on remotely retrieved on any mobile device.

The benefits:

1. Important data can be collected, stored and managed centrally in one place

2. Relevant information based on this data can be obtained anywhere, anytime

3. Subsequently, gained insights and knowledge can be used to optimize processes

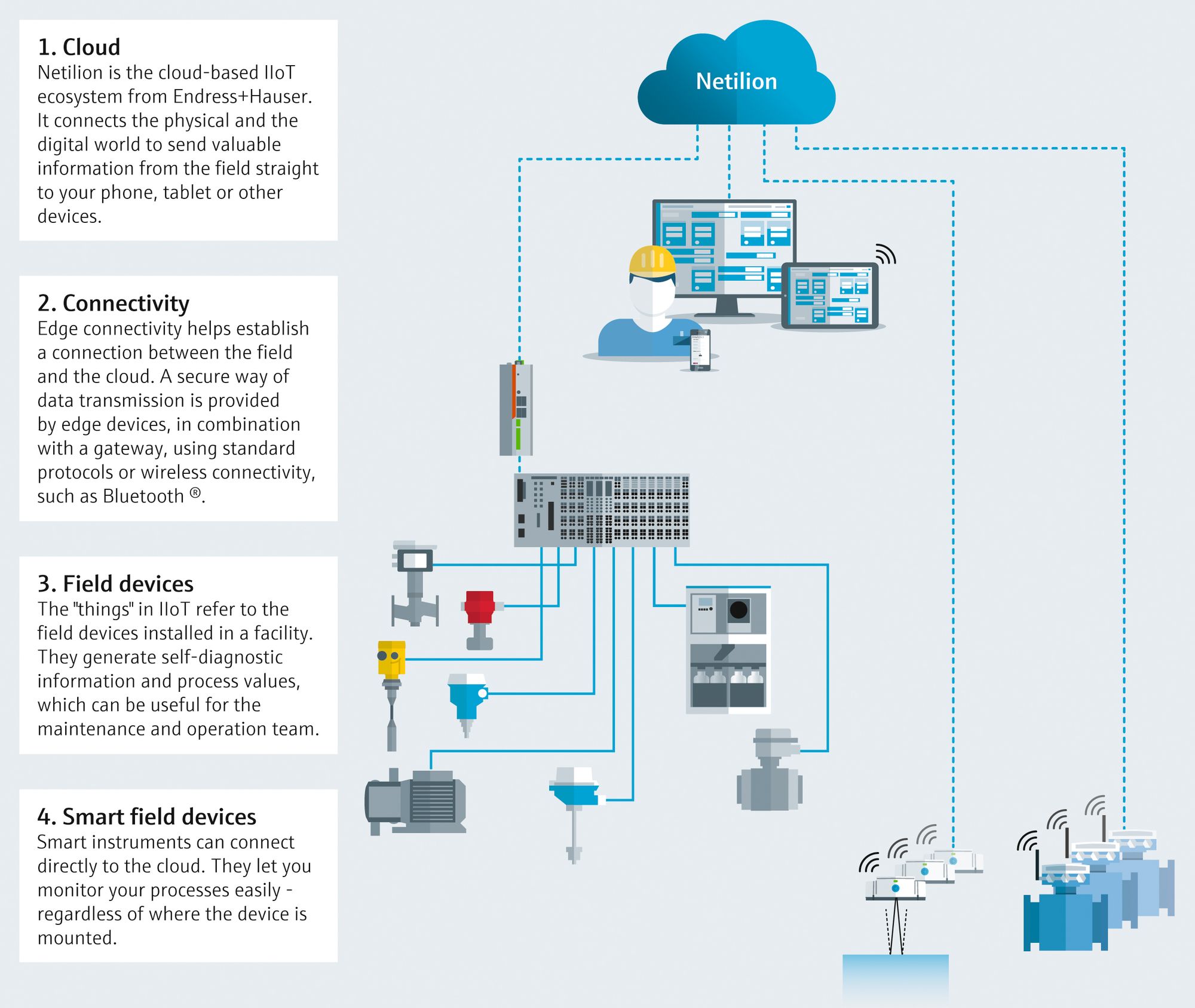

Netilion is the cloud-based IIoT ecosystem by Endress+Hauser, designed for industrial processes. It connects the physical and digital world to send valuable information from the field straight to your mobile devices and offers a wide range of predefined applications from remote health and value monitoring to file and obsolescence management:

What is it with connectivity and what do I need it for?

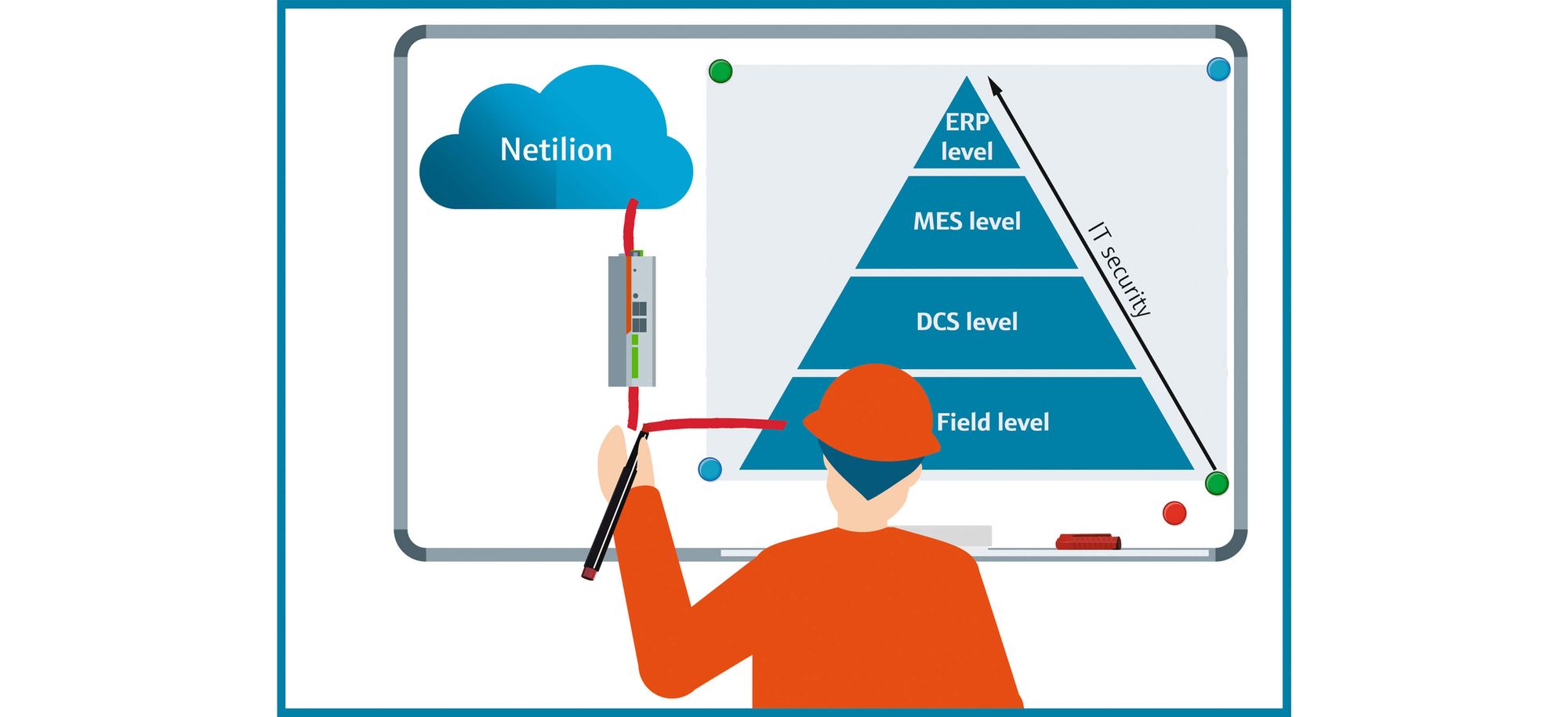

Connectivity plays a crucial role in the Industrial Internet of Things (IIoT). It allows the integration of field devices into an IIoT ecosystem. This enables you to remotely monitor your assets, collect data from the field, and improve decision making for industrial processes.

What you need is an edge device to make the connection between the field and the IIoT ecosystem. For its IIoT ecosystem Netilion, Endress+Hauser offers an edge device (FieldEdge SGC500) that is suitable for various standard protocols:

- HART

- WirelessHART

- PROFIBUS

- EtherNet/IP

Even a Bluetooth® transmission is possible (with the Field Edge SGC200). However, depending on the type of equipment, additional gateways or adapters may be required to establish the connection. Once set up, IIoT connectivity provides seamless data flow and access to critical information.

The FieldEdge device enables connectivity to the cloud without touching the control system, allowing for access to data from the field. This provides additional information without the need for major changes to the system.

What's the field devices' role in the IIoT? What about 3rd party devices?

The "things" within the Industrial Internet of Things (IIoT) refer to assets installed in a facility. Today, the majority of field devices are already intelligent and have the capability to generate self-diagnostic information and various process values, more than what is typically displayed in the control system. This information is of great value for the maintenance and operations team, but it can only be utilized if it is not locked in the device.

Accessing and analyzing field data provides a deeper understanding of the installation, which in turn leads to faster reaction to unexpected events, such as device errors, and facilitates data-driven decision making.

The special advantage of the IIoT ecosystem Netilion lies in its multi-brand approach. Netilion provides diagnostic information for devices from more than 50 manufacturers. This makes maintenance and operation in a plant with multi-vendor equipment much easier.

Can I connect my field devices directly to the cloud?

A direct, wireless connection between a field device and the cloud without the need of an edge device, gateway or adapter is possible thanks to cloud-ready, smart transmitters. Using cellular networks, they send values, diagnostics, and configurations directly to the cloud. To operate autonomously, such field devices are often battery-powered. For these reasons, they are especially useful in remote installations without any other infrastructure or power supply.

The flowmeter Promag W 800 is one example of a smart field device, targeted at off grid applications in the water industry. By using a cellular radio module and a data logger, the flowmeter can send and receive data – without the need of a power grid.

Another example is the level meter Micropilot FWR30. The wireless and battery-powered sensor ensures reliable and remote level monitoring in tanks, silos and containers, which are often stored remotely or in changing locations.