How to increase safety in tailing dam applications with WirelessHART and IIoT services?

After many accidents with tailing dams, it's important to learn how to increase the safety of it, applying WirelessHART and IIoT service solutions.

If have you have never heard about tailing dams, then most probably you are not involved in the primaries. Stay around because tailing dams are a critical topic nowadays after all the problems with this application in Brazil in the last year.

The idea today is to dive into the application, understand what tailing dams are, why they exist and what the solutions are to help in their monitoring.

Of course, there are different types of monitoring in this application, and most of them are used in combination to provide more data to the operator.

Today, I will share one of these possibilities and explain why it’s crucial to have online monitoring in this application. Finally, I will also share the benefits of implementing the monitoring system together with an IIoT health service, and how this service can add value for you.

As usual, let’s find out together how to improve the safety of tailing dams by implementing wireless and IIoT service solutions.

What is a tailing dam?

When I refer to a tailing dam, I am talking about mining companies that must build a large structure to store all the waste from the mining process. As you can see from the way it works, tailing dams are permanent structures that hold all this waste.

So, when you see a tailing dam, you’re looking at a pretty gigantic structure. I remember the first time I visited a tailing dam back in Brazil. I saw it first from far away, and I could see just how big it was. Then, when I was there to check the application I will talk about today, I couldn’t guess how big the place was. Very impressive.

Usually, you will find tailing dams in different mining processes, such as the extraction of uranium, gold, copper etc. Based on some research I made, Canada has the biggest tailing dam in the world - I can’t even imagine the volume of product at this place. It’s 18 kilometers long and something like 40 to 80 meters high. Big huh?

On top of that, an article from the Economist says we have already about 3500 tailing dams in the world. The world is discussing them after the recent incidents with two tailing dams in Brazil. Society is asking itself how safe is this application? What happens if a dam fails?

For sure, as any industrial application, there is risk involved, but how can automation help to provide safety monitoring?

How does a tailing dam work?

In a mining process, a lot of waste is created during the extraction of the valuable component. The waste is a combination of many things, including rock, sand, chemical reagents and the water used to extract the commodity.

All this waste is pumped into the tailing dams for settling and separation. So, to ensure the safety of this application, it’s essential to implement a system to measure the water and moisture in the tailings dam wall and to monitor the structure with e.g. extensometers and contractometers.

Ok, but there are different types of tailing dams, below I listed the types and how they are built.

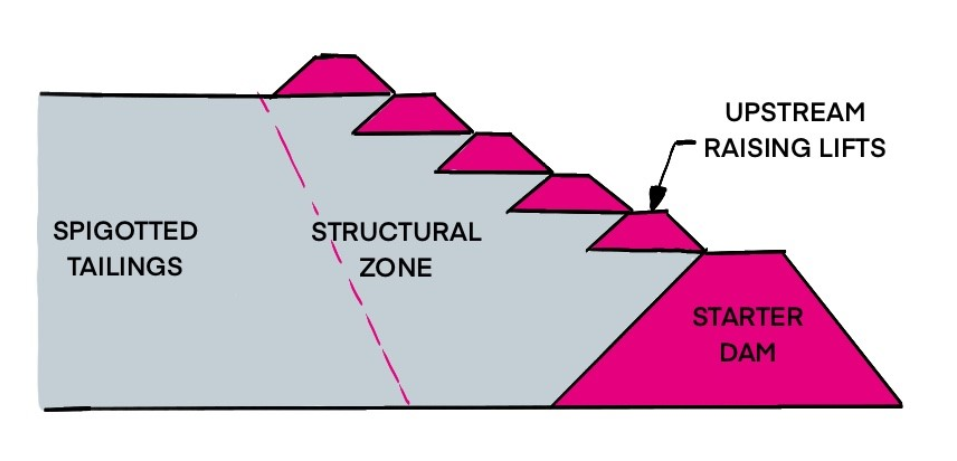

Upstream Tailing Dams:

Upstream tailing dams are raised progressively upstream of a starter dam, the tailings materials being incorporated into the dam support.

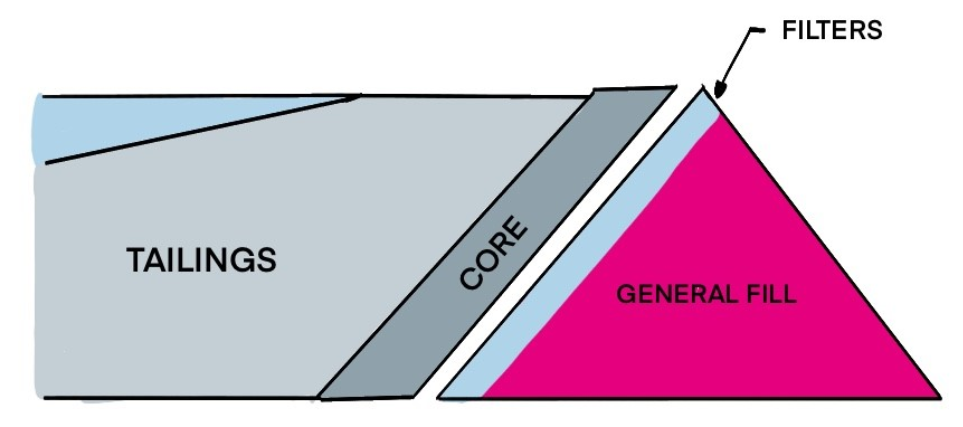

Downstream Tailings Dams:

With downstream tailing dams, the structure is raised progressively downstream of the starter dam

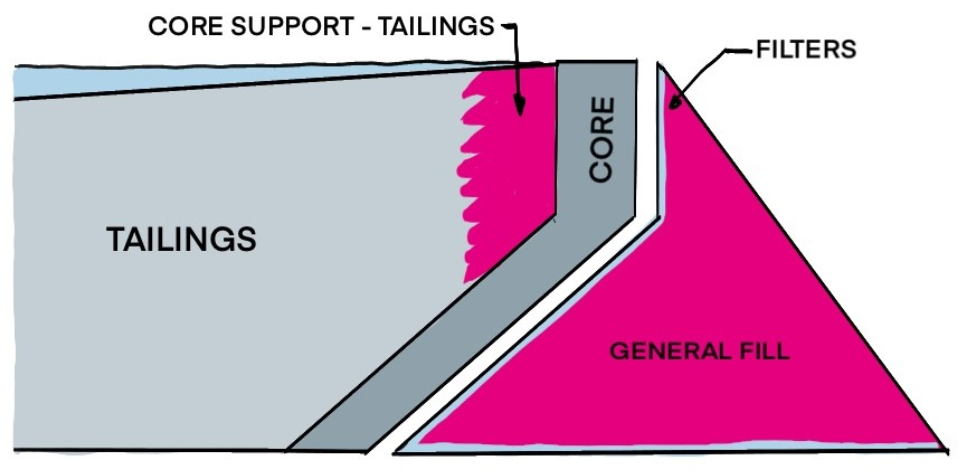

Centreline Tailings Dams:

Finally, the centreline tailing dam is built progressively on top of the centreline of the starter dam.

How is monitoring done in a tailing dam?

Nowadays, it’s common practice for the monitoring of the water and moisture level in the dam wall to be done manually by the operator. It means the monitoring is sporadic because there are many points to be checked.

Furthermore, when you have monitoring that depends on someone measuring and reading values, you can have many problems in how the measurement is made. This impacts the quality of the information.

Each operator can have a different procedure to read and interpreted the data, before noting the result and later transferring it to the computer.

As you can see, there is plenty of room for errors in this procedure. In addition, when you have someone doing the measuring only from time to time – maybe every 15 days or even worse, monthly - you don’t have enough data concerning the water or moisture level.

In this scenario, automation is the right way to collect the data more often, such as every 5 minutes, and provide a far more accurate measurement.

How to improve your tailing dam safety?

When we change from manual monitoring to an automatic system, safety is increased because you get more data than before and it’s more accurate. In a tailing dam, it’s possible to have many types of measurement, such as flow, level, displacement and strain.

Smart solutions can provide online data to the control system, eliminating human errors involved with reading and noting the values. As an example, let’s look at ground water level measurement using WirelessHART solutions.

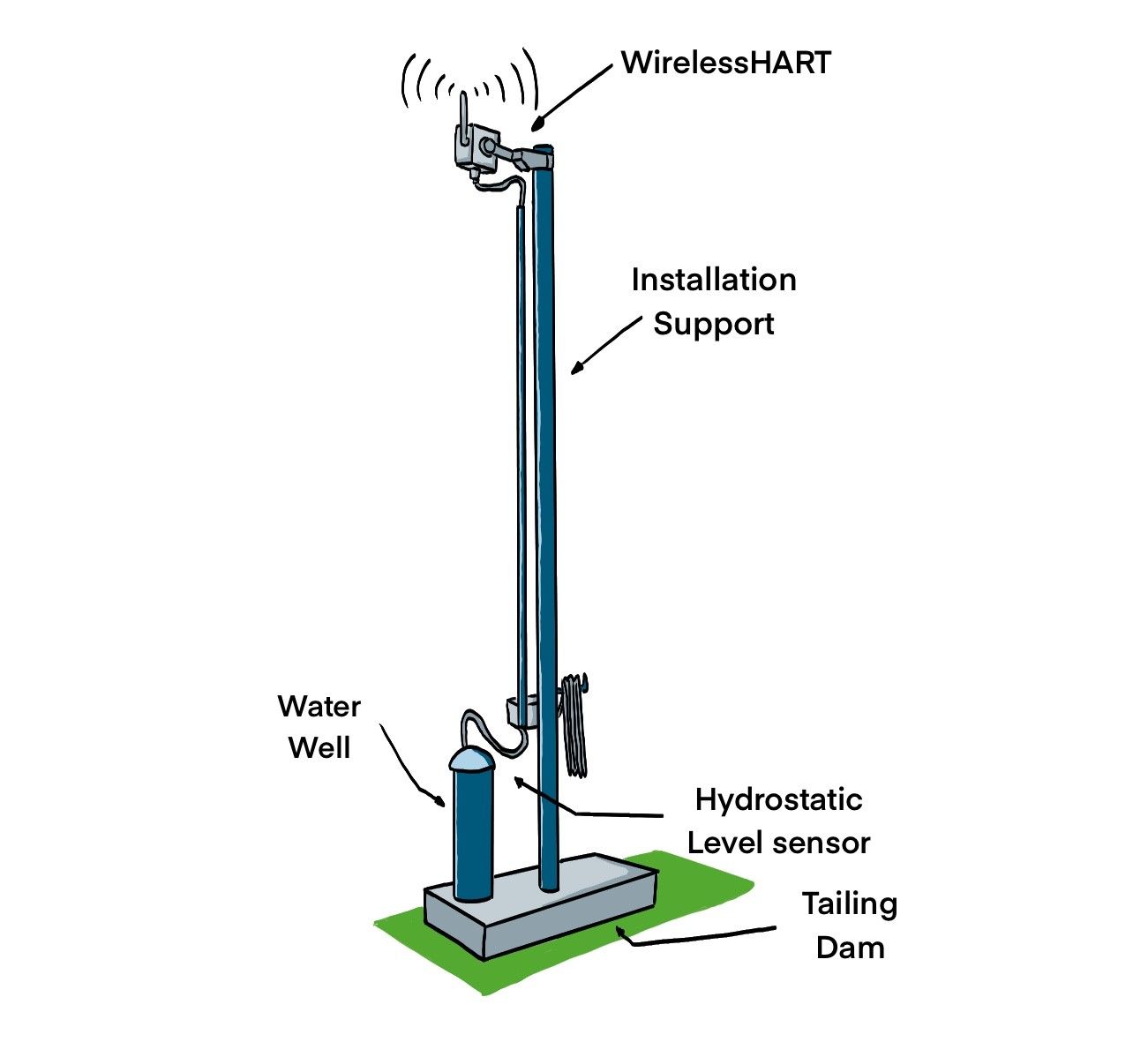

In this application, you need a hydrostatic level sensor installed in a PVC or any other type of tube within the water well. The hydrostatic level sensor is equipped with a WirelessHART adapter, such as the WirelessHART adapter SWA70.

The adapter provides the energy to the level sensor, and you can it set up to measure every 10 or 15 minutes. This will give you far more information than a manual measurement every 15 days.

You can also use an ultrasonic level transmitter to measure the level of the tailing dam, again sending the information with a WirelessHART adapter.

The WirelessHART solution helps to decrease the cost of investment in automation, and it doesn’t require a lot of infrastructure. You’ll only need a WirelessHART gateway, like the Fieldgate SWG70, to collect all the data.

Finally, the setup of the Wireless network is simple, and all the information can be easily integrated into any control system through open protocols, such as OPC or Modbus.

How can IIoT improve the application?

The wireless solution will not only provide all the measurement values, it also provides device diagnostic information. Now, if you want straightforward access to the health information of your devices, an IIoT health service, such as Netilion Health will provide it wherever you are.

To implement the health monitoring in your system and increase the safety of the application, you just need to connect an edge device to the wireless gateway. The edge device will then act as a bridge between the field and the IIoT cloud solution.

After an effortless setup, it’s possible to get access to all the health information with your smartphone, tablet, and laptop. If anything happens with a measuring point, you are informed immediately.

You can have a look at the Netilion health here. Have a look and see what information you will get, no matter where you are. That’s it! WirelessHART with Netilion Health is one of the most powerful solutions to improve the safety of your tailing dam.

If you liked this article, don’t forget to share it on social media using the #Netilion.

Cheers