How to take the first steps towards IIoT using WirelessHART

Without online health monitoring, more time and money are spent on maintenance.

Today, let’s start with a question. When you hear about the Industrial Internet of Things, what picture do you have in your mind? Okay, let me try to guess: your company is still using 4-20 mA signals and you can’t see any change in the short-term, right?

All of your field devices have HART communication, though, but you use it mainly for reading device status messages or changing configurations. Am I right?

What if I say that IIoT implementation can be quickly done in your 4-20 mA/HART system without any changes? Yes, your HART devices have the same level of intelligence and information as most digital devices. On top of that, the acquisition of this information and its integration into a cloud service is far simpler than you think!

Stay with me, and let’s have a look at the IIoT concept and then understand how simple it is to implement, allowing you to take the first steps towards IIoT in your plant.

What’s IIoT?

Back in the so-called third industrial revolution, the idea was to automate machines and processes. This simply meant implementing a system that was able to measure a particular process value, apply a control algorithm to it and then use the resulting output value to e.g. actuate a valve or change the speed of a pump motor.

Automation saved time and manpower as well as increasing the efficiency and the quality of production.

Nowadays, when we talk about the fourth industrial revolution, IIoT or Industry 4.0, the idea is to efficiently acquire masses of data from smart sensors and machines. This allows the exchange of data for analysis aimed at optimizing the process.

The results are available in a number of applications, e.g. for analytics, health information or a document library, each with a clear user interface displaying all essential information.

What’s the potential of IIoT in an industrial environment?

The majority of the valuable information lies (dormant) in the field. This is information that could help you to improve your process and avoid unplanned shutdowns in your plant. When you think about smart devices, you probably see only today’s devices that employ innovative communication technology, right?

Nonetheless, HART field devices also have intelligent device management (IDM), as found in FOUNDATION Fieldbus (FF) and PROFIBUS (PB) field devices.

However, whereas FF and PB field devices communicate digitally with the control system, your HART devices are probably just sending dumb 4-20 mA signals to the controller. Since you are not using HART communication, they are keeping the best of their information to themselves.

But all is not lost! Nowadays, IIoT solutions can collect and analyze HART device data independent of the control system and provide relevant insights for your process. This impacts directly on process improvement, as health analyses are known to decrease the number of unplanned repairs and unscheduled shutdowns.

What’s WirelessHART?

There are various types of wireless communication, perhaps the most well-known being WirelessHART and Bluetooth. Both networks work reliably in an industrial environment, providing secure and robust connectivity.

Let’s talk about WirelessHART. Although some people are still not familiar with it, WirelessHART has established itself in many different industries around the world. The protocol was developed in 2004 and it had its market launch in 2007. In 2010, it became an International Standard, IEC 62591.

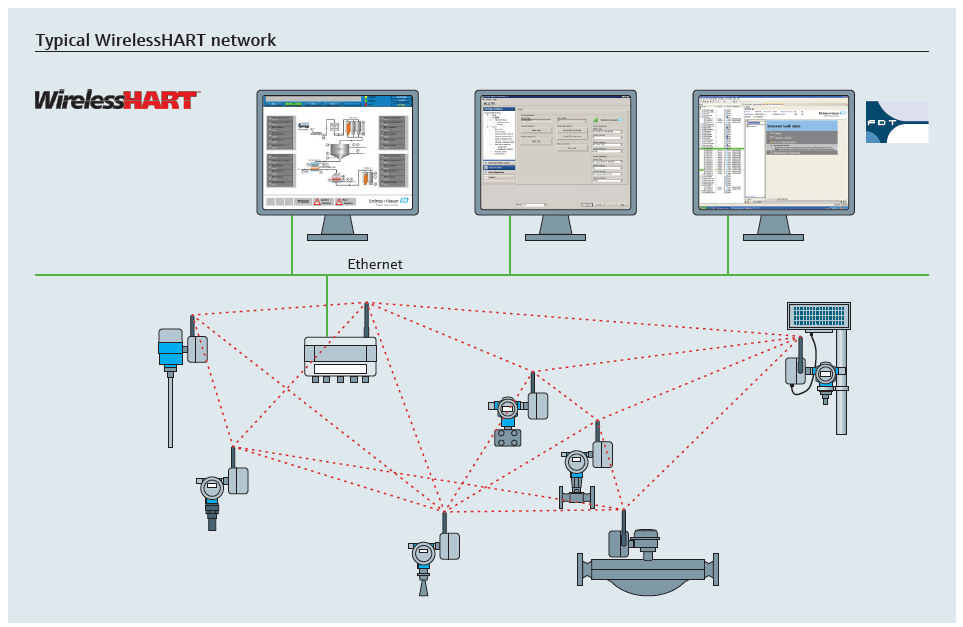

Put briefly, WirelessHART works at a frequency of 2.4 GHz, using the Time Division Multiple Access (TDMA) mechanism to synchronize all devices in the network, each of which communicates with a gateway.

In addition, WirelessHART works with a mesh network based on the IEEE 802.15.4. This combines two methods that ensure a reliable and secure network: Frequency Hopping Spread Spectrum (FHSS) and Direct Sequence Spread Spectrum (DSSS).

Devices can have WirelessHART built-in or they may be equipped with WirelessHART adapters. The latter will upgrade 4-20 mA/HART devices and analog devices to wireless instruments.

How is WirelessHART implemented in IIoT applications?

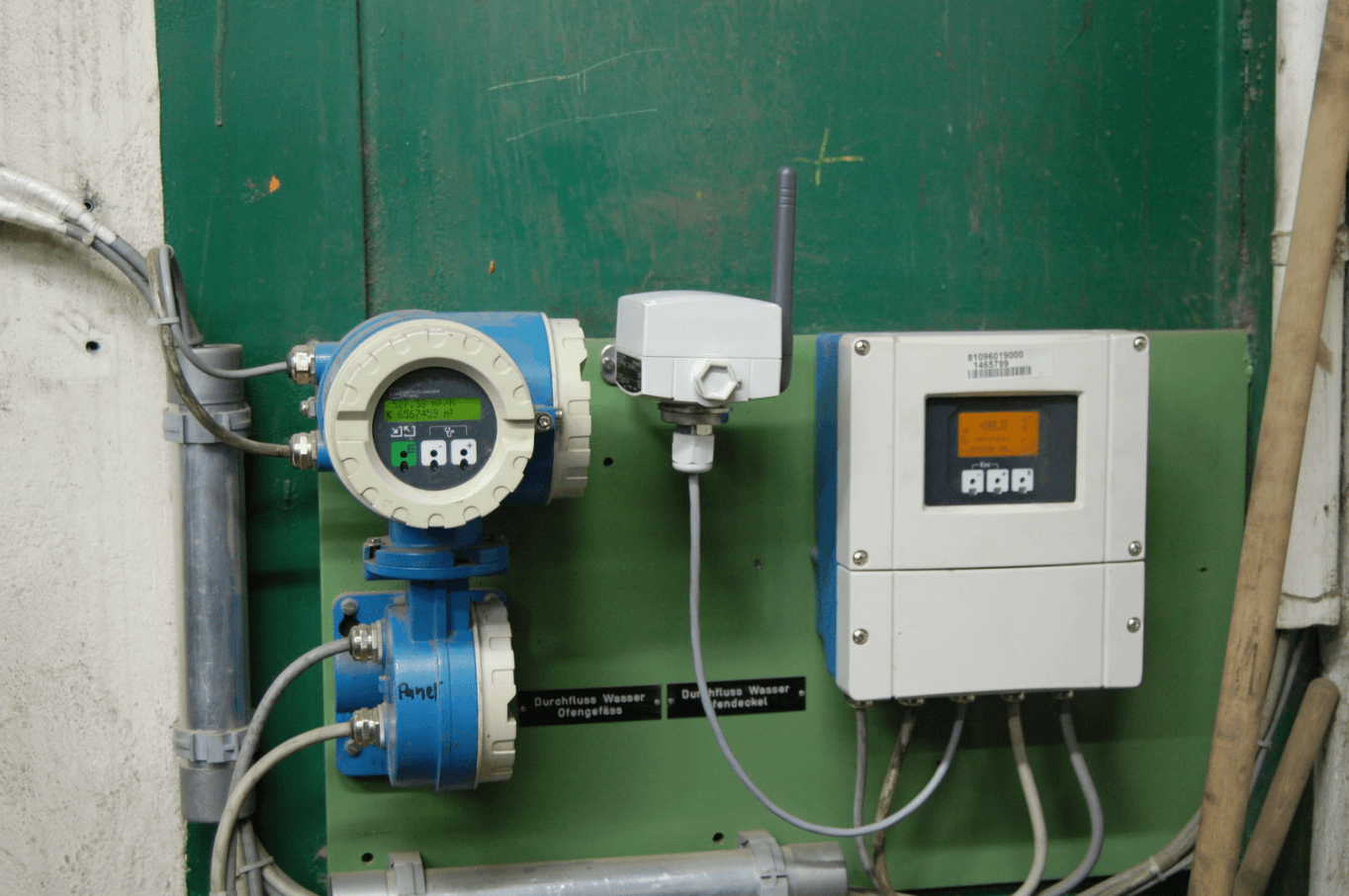

If you already have a plant with HART field devices that connect to the control system using only 4–20 mA signals, a WirelessHART adapter is the answer. This is a straightforward way of collecting all their smart information and delivering it to the gateway.

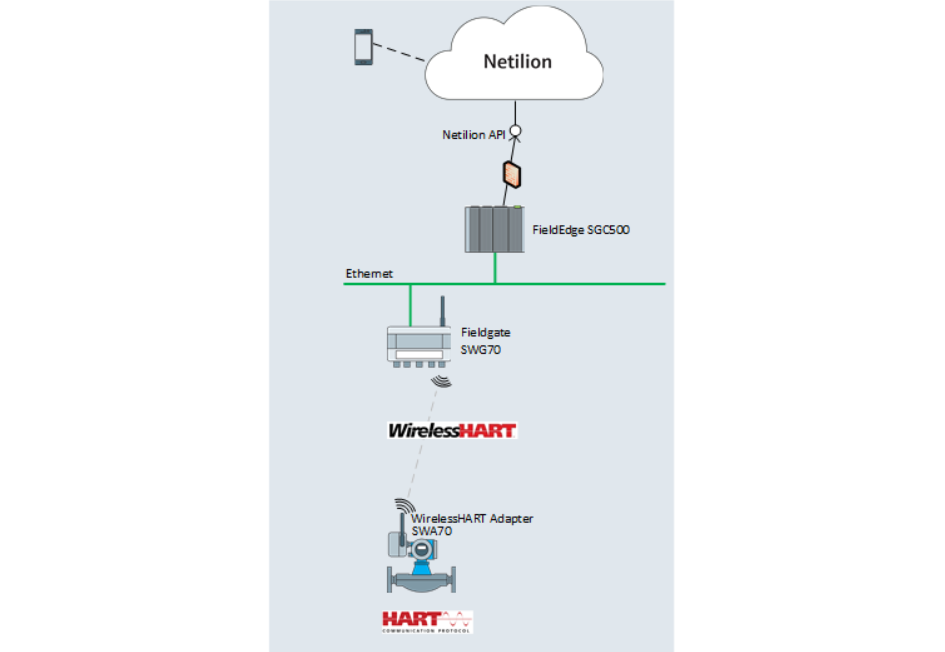

This can then transmit the information to an Edge Device, which will safely integrate it into a cloud service.

Depending on application, a WirelessHART solution normally saves more time and money than using a multiplexer to collect the same data. The WirelessHART adapter can be battery powered or it can get its energy from the loop-powering of your device.

It can be installed directly on the device or remotely. Adapters can be added quickly and easily, without significant modification to your plant infrastructure.

Thanks to the technical characteristics of the network, you can expand a network or have more than one network in your plant. There are some rules for the network sizing, but a trustworthy provider of IIoT services working with HART connectivity such as Endress+Hauser will give you all necessary support regarding the network architecture.

What are the benefits of retrofitting your critical tags?

Critical tags need constant monitoring if an unscheduled shutdown in your process is to be avoided. In most scenarios, the retrofitting of standard digital solutions in an existing 4-20 mA infrastructure will result in high investment costs.

WirelessHART adapters, however, are a straightforward way of obtaining the benefits of online monitoring with minimal effort and investment.

Without online health monitoring, more time and money are spent on maintenance. When a device has an issue, the field engineer takes needs more time than with an IIoT health monitoring service to figure out what’s going on, to find the error and to fix it.

A high-performance online health monitoring service like Netilion Health can continuously track your field devices. By having the network connected to the cloud through an Edge Device, you also have access to all critical data wherever you are.

This technology is based on robust and stable wireless communication already implemented in many applications using the HART protocol around the world. Please note that all of these sensitive data require special protection. Choose an IIoT solution with an Edge Device is that is compliant with legislation, standards and data security guidelines.

If you wish to learn more about the cybersecurity of IIoT services in general and of Netilion in particular, you can read our article: Cybersecurity in industry plants with IIoT: What really counts …and how safe is Netilion?”

Simple steps for health monitoring of your critical tags

Now we know how WirelessHART can make IIoT implementation simpler than ever, but how does it work? Let me describe the simple steps to start the online monitoring of your critical tags using Netilion Health.

- Find the critical devices in your plant: First, you need to find out which measurements and devices are critical in your plant. Then, you can work together with Endress+Hauser to size your WirelessHART network and find out how many wireless adapters, repeaters and WirelessHART gateways are necessary.

- Equip these devices with wireless adapters: Each critical device requires a single adapter, which you can install locally or remotely.

- Connect to the wireless gateway: Give all the adapters a network ID and join key and they will connect automatically to the wireless gateway. The wireless gateway collects all the information from the field devices.

- Connect the wireless gateway to the Field Edge SGC500: The WirelessHART gateway SWG70 is Netilion Ready, which means that it can be connected to the Edge Device SGC500 after setting the SWG70 HART address and port according to specification. Then connect the Field Edge to the Internet.

- Configure the Edge Device and finalize the connection to Netilion: Complete the installation by configuring the Edge Device SGC500 to connect to your Netilion account.

Once these steps are done, you’re ready to start collecting data in the Netilion Ecosystem and can consume them via the so-called Netilion Services. The Netilion Heath service, for example, only requires these simple steps to provide in-depth knowledge of your assets using your smartphone, laptop, or tablet, wherever you are.

In addition, you can track all the information of your assets, have a graphic overview of events and access health history for in-depth insights. Do you want to see it working? Try it for free, and see the magic happening.