#Workingfromhome – how IIoT services can help your plant go digital

This pandemic will end, but the world won't be the same. Digitalization accelerated because of this unusual event, and it’s likely to remain and expand.

The COVID-19 pandemic happened so fast that most companies weren’t ready. One day everything was running smoothly, and the next you found yourself working from home. This unusual situation created a race against the clock to move small businesses and large to the digital side.

Many B2B and B2C companies lacked the structure and solutions to set their employees up to work remotely. Some even lacked a solid online presence of any sort, flattening their businesses overnight.

On the B2C side of the story, I helped several small businesses in my mother's hometown set up online with basics like social media, apps, and ad budgeting. That way they could run their companies digitally, making money even with their doors closed.

On the industrial side, many friends told me that their plants struggled to manage operations with fewer people on-site and no smart data from the field, often reducing production and quality. Maintenance suffered as well because they couldn't pull items they needed from stock.

Today, I’ll give you some ideas on how you can go digital with a couple of clicks and maybe some basic installation. These ideas could improve productivity, reduce or avoid shutdowns, and allow remote work without any problems.

Asset health monitoring

A friend told me recently that he and his colleagues couldn’t pull new items from their stock. They could do it in an emergency, but nobody knew what was even happening in the plant, much less whether it could be considered an emergency. (They are trying to save money.)

It's time to think differently, people. All these devices in my friend's plant have smart diagnostics, so why not use them? Sure, analog is robust and all that, but you can still collect and use smart data even if you prefer to control your plant with analog systems.

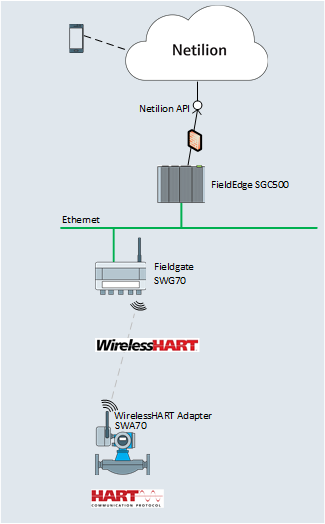

WirelessHART is one of the best ways to collect this data. Install a wireless adapter on your field device, and you can transmit valuable information in parallel to your gateway. And an edge device can create a bridge between the field and the cloud with secure and encrypted communication from the gateway.

Once you send your data into the cloud, you can access and analyze it using a cloud service. For instance, Netilion Health is a great solution to monitor the health of your devices. With an online visualization, you can plan spare parts, replacements, and so on.

Maintenance gets smarter too, with access to the right information. The maintenance team can review their data anywhere they can get internet, speeding up decisions, avoiding unplanned shutdowns, and improving repair planning.

Remote monitoring

It might sound crazy, but many companies still run parts of their processes without automation. Yes, plant operators have to walk across the plant regularly to write down process values and walk back to report any issues. In some places, they have to drive to remote sites just to do that!

Look around, and you can spot small projects that could use a digital monitoring solution. Back in my field days, I did several myself to collect information and concentrate it somewhere for the plant operator. Even though I’m not that old, things have changed a lot in the four years since I stopped visiting the field.

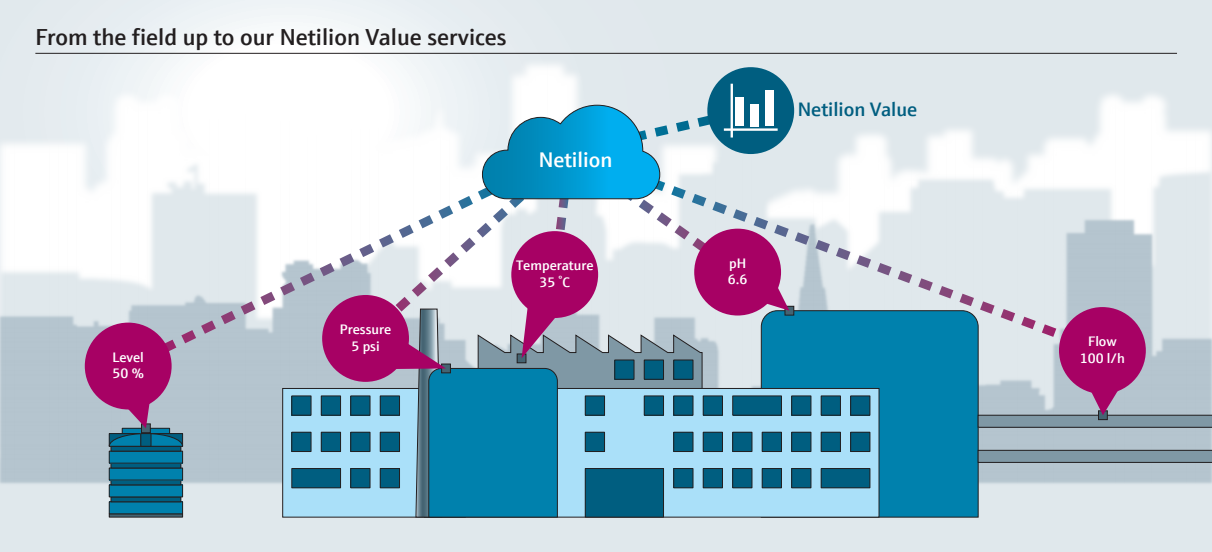

Today, a cloud service can give you access to all your remote applications without wasting time driving or walking there. For example, Netilion Value supplies some nifty features to help you efficiently monitor your processes.

Together with digitalization, this sort of service can vastly improve the efficiency of your plant. You can get devices with a direct connection to the cloud, such as the Micropilot FWR30 IIoT radar for level monitoring. You can also use an edge device to go beyond the level and monitor all your process variables.

This system provides a history of all your processes, alarms, and other features. Best of all, the plant operator can sleep in peace at a desk instead of – just kidding! Jokes aside, plant operators can focus on valuable tasks in the plant, making processes run more smoothly than ever.

Access to knowledge anywhere

Having the history of a device can be essential to troubleshooting it, and the right documentation can save valuable time. Today, you can get all your device's information in the cloud.

IIoT services offer you the chance to create a digital twin of your plant in the cloud that stores the histories of the assets. For instance, you can save all the technical documentation for devices, drives, DTMs, calibration, and technical reports.

When you need to troubleshoot a problem, analyzing the history of the device makes it easier. To create a digital twin, you can use the app on your phone or an edge device to make it happen. It’s that simple.

I wish I had access to such a system when I got stuck troubleshooting a field device. I used to print out parts of technical manuals and write down recommendations, then slog out there to see if any of it applied. Sometimes I had to come back for more info.

Yeah, that was buckets of fun. But now everything is digital and more comfortable than ever. Enjoy it!

If you learned something useful from this article, please share it with your colleagues on social media using the #Netilion tag.

Stay safe, and have a good one!