7 reasons why you have to apply WirelessHART with IIoT after reading this article.

WirelessHART is one of the most relevant networks for providing the seamless integration of your plant into a cloud solution. Let’s learn 7 reasons why you have to apply WirelessHART with IIoT solutions

Today, I decided to take up a challenge and give you 7 reasons why you will be ready to implement WirelessHART and IIoT Solutions after you finish reading this article. Yes, even though wireless is already a reliable option on the market, the majority of the users are still not using it, leaving the relevant data from the smart devices in the field.

For many years, when wireless was not yet consolidated, I pushed this topic in different industries together with salespeople in face to face meetings. I realized then, and it still applies today, that WirelessHART is a technology where users say, “I only believe in a technology if it works at my plant.” Great - I used to love doing a field test and showing the technology working after a speedy implementation.

I don’t think this scenario will change, even with the tools available for creating the network architecture. Users will still like to see the solution working before buying it.

However, there are many questions regarding wireless I can answer here and maybe somehow avoid the barrier to the first test and the subsequent implementation of the technology.

The idea today is to go through concerns regarding WirelessHART and IIoT solutions. I will provide the reasons why you don’t need to worry about it anymore. On top of that, I will highlight the real benefits that WirelessHART, together with IIoT, can bring to your daily work.

Stick around, and let’s find out the answers together.

My company is not ready for wireless technology.

Your company not being ready for wireless is the first concern regarding the technology. The reason for this is uncertainty related to the knowledge necessary to deal with it and how complex its application might be.

First off, all the companies are ready to implement this type of technology. The knowledge necessary to maintain the network is simple, and the vendor usually provides training for the local team.

Usually, the training will explain the concept behind the technology and what’s necessary to it set up, to change a device and to troubleshoot the network. Most of device monitoring can be done using any web browser accessing the gateway. Furthermore, the associated wireless adapters are set up using traditional automation tools.

Second off, the implementation of the WirelessHART network is also very simple and can be done with a couple of hours. When we talk about wireless adapters, these can be installed in different ways on any existing or new field devices supporting 4-20 mA/HART communication, irrespective of vendor.

After a simple installation on the field device, the adapter is given the Network ID and Join Key, after which it is automatically integrated into the network – it works just like your WLAN at home! Then, all the configuration can be done remotely using a web browser or software such as FieldCare.

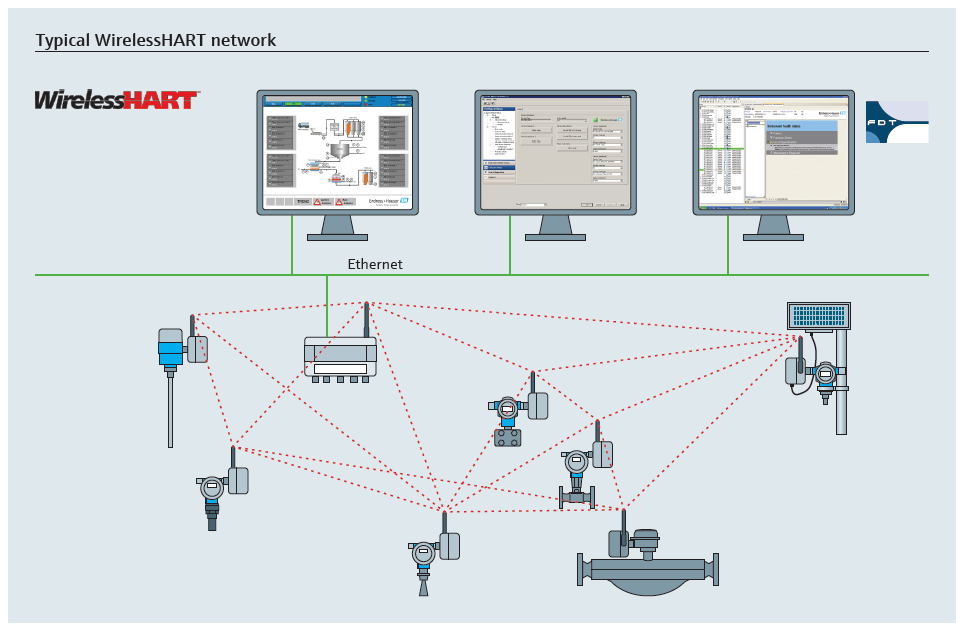

The WirelessHART network is integrated into the control system by means of standard and open protocols such as OPC, Modbus TCP/IP, HART-IP, Modbus RS-485 and more.

Last off, you don’t need to make your plant 100% wireless, but can start with small projects, adding new devices when necessary.

We don’t have a big project for wireless at the moment.

That’s OK; you don’t have to start with a big project to implement WirelessHART technology. The technology provides you with the possibility to start small and then add new measuring points when necessary.

Many applications where I had the chance to implement WirelessHART were simple projects for monitoring. The customer wanted to test the technology and at the same time, save money on installation costs and service hours.

On top of that, there are excellent benefits from getting access to the field devices using a remote solution. You can stay in your air-conditioned or heated room, depending on where you are in the world.

Solutions such as the Netilion Health, Netilion Analytics and FieldCare give you the power to check the health status of your field devices, manage your installed base and set everything up remotely.

You can start your network, for example, by using WirelessHART for level or temperature monitoring in stock tanks. Furthermore, energy monitoring systems can be easily implemented with WirelessHART solutions. The same applies to health monitoring with WirelessHART and IIoT services, such as Netilion Health.

After you have implemented it in simple monitoring points, you can go bigger. That means find a big project where you need a reliable network to straightforwardly provide all the data and process measurements.

Is WirelessHART communication secure enough to have in my industry?

Yes, WirelessHART and the IIoT solutions have a high level of security. I will give you more information regarding the protection of WirelessHART networks, but you can read another article where we talk about the security in an IIoT solution here.

I will try not to dive too much into the technical details regarding the security of the network, but I have to mention some technical points - sorry about that. WirelessHART networks are robust and secure; we have a lot of technology protecting the system and the data exchanged in the network.

For instance, the network uses industry-standard 128-bit AES encryption, a unique encryption key for every single message. Furthermore, you have device authentication of the network and the verification of the data integrity. Then, when a device joins the network, you can have automatic or on-demand encryption keys.

The network itself is also protected. It has multiple levels of security keys before a device gets access to it. Channel hopping also enhances the security and protection of the network. Coexistence with other networks is also ensured.

Lastly, the WirelessHART is entirely secure from the cyber attacks that sometimes happen in WiFi networks. Networks have already been implemented in applications ranging from mining to offshore oil platforms, proving their robustness, reliability, and security.

I don’t see the benefits of the WirelessHART implementation in my 4-20mA plant.

OK, but you can get a lot of information from your field devices and then change how you deal with daily issues. First, a 4-20mA plant today already has a majority of smart sensors in the field, but nobody, or just a few users, uses the information they provide to improve daily tasks.

For instance, if you have radar level transmitters from Endress+Hauser and you only use the 4-20mA signal, you don’t get access to all the smart information they have, e.g. Heartbeat technology.

Another point is, when a problem happens with a field device, you are blind unless you have data regarding the health status. If you collect this information using an online solution, you could see what’s going on and solve problems faster or even avoid this kind of issue in the field.

WirelessHART adapters can be fitted to your field devices without affecting the 4-20mA signal. They will collect all the smart data provided by the HART protocol and transmit them over the wireless network.

When the data arrive at the gateway, you can read the information using a local solution like FieldCare. Alternatively, you can opt for a cloud solution, e.g. using an edge device and Netilion Health, and then get access to it anywhere you happen to be.

Additionally, if you have a cloud solution with an edge device, you can create a digital twin of your plant and have a better picture of the reality in the field. For example, by applying the Netilion Analytics.

Configuration of a WirelessHART network and IIoT is too complicated.

Like any other digital network, there is a “philosophy” of how to set it up. It is, however, straightforward and as soon as you get familiar with the step-by-step approach, your technical team will be able to do it quickly.

Just to show how simple it is, I’m going to try to summarize the configuration by taking you through it step-by-step.

First, the WirelessHART Gateway is given a Network ID and a join key- this gives a unique name to the network and the “password” needed to get access to it.

Next, you fit the WirelessHART adapter onto your field device. As soon as the device is connected, you give the adapter the Network ID and join key so that it can access the network.

You also need to tell the adapter what device information it should transmit over the network, e.g. primary value, secondary value etc.

Once this is done, you tell the device to join the network – the rest happens automatically.

When all the devices have joined the network, you must integrate the information from the gateway into the control system or SCADA. For this, you have many possibilities, such as OPC, Modbus TCP/IP, Modbus RS485, EtherNet/IP and so on.

The integration of the WirelessHART gateway into the control system will be very familiar to automation people. The gateway, as I mentioned above, uses open and accessible protocols to help it happen.

This, of course, it is a concise summary of how it is done. You can also change the order of the procedure if you want. Most vendors will anyway support you with training and help with the first integration of WirelessHART in your plant.

I don’t have a unique vendor in my plant; I can’t use this WirelessHART adapter.

Yes, you can. The WirelessHART can be fitted to any vendor’s device that uses the HART protocol or even only 4-20mA (particular application). That means, it doesn’t matter what vendors you have in the field. With a tool such as FieldCare, you need only the right DTM file to collect and read the information.

Now, for some IIoT services, it’s crucial to check the compatibility between the field device and the online monitoring. The trend with IIoT services, however, is to support practically all vendors in short to middle-term.

It’s too complicated to integrate a WirelessHART network into an IIoT solution.

As I mentioned earlier in this article, the configuration and implementation of the technology is super straightforward. I have also written another article going into more detail and there you find further information regarding IIoT and WirelessHART.

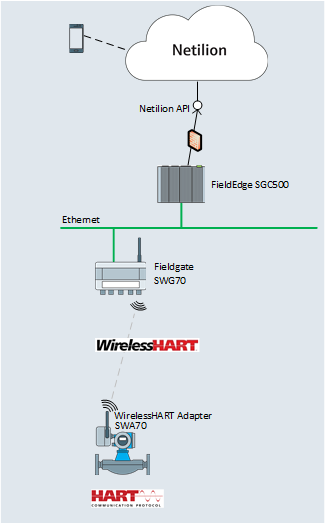

Let me list the procedure to get your WirelessHART network into the cloud, focusing first on the critical assets.

- Find the critical devices in your plant: First, you need to find out which measurements and devices are essential to your plant. Then, you can work together with Endress+Hauser to size your WirelessHART network and find out how many wireless adapters, repeaters and WirelessHART gateways are necessary.

- Equip these devices with wireless adapters: Each critical device requires a single adapter, which you can install locally or remotely.

- Connect to the WirelessHART gateway: Give all the SWA70 adapters a network ID and join key, and they will connect automatically to the wireless gateway. The wireless gateway collects all the information from the field devices.

- Connect the wireless gateway to the Field Edge SGC500: The WirelessHART gateway SWG70 is Netilion Ready, which means that it can be connected to the Edge Device SGC500 after setting the SWG70 HART address and port according to specification. Then connect the Edge Device to the Internet.

- Configure the Edge Device and finalize the connection to Netilion: Complete the installation by configuring the Edge Device SGC500 to connect to your Netilion account.

That’s it, simple, huh? I think I am done today. Are you ready to apply WirelessHART and IIoT in your plant? I am sure you are!

If you liked this article, don’t forget to share it on your social media using #netilion

See you soon!